CNC laser GAR

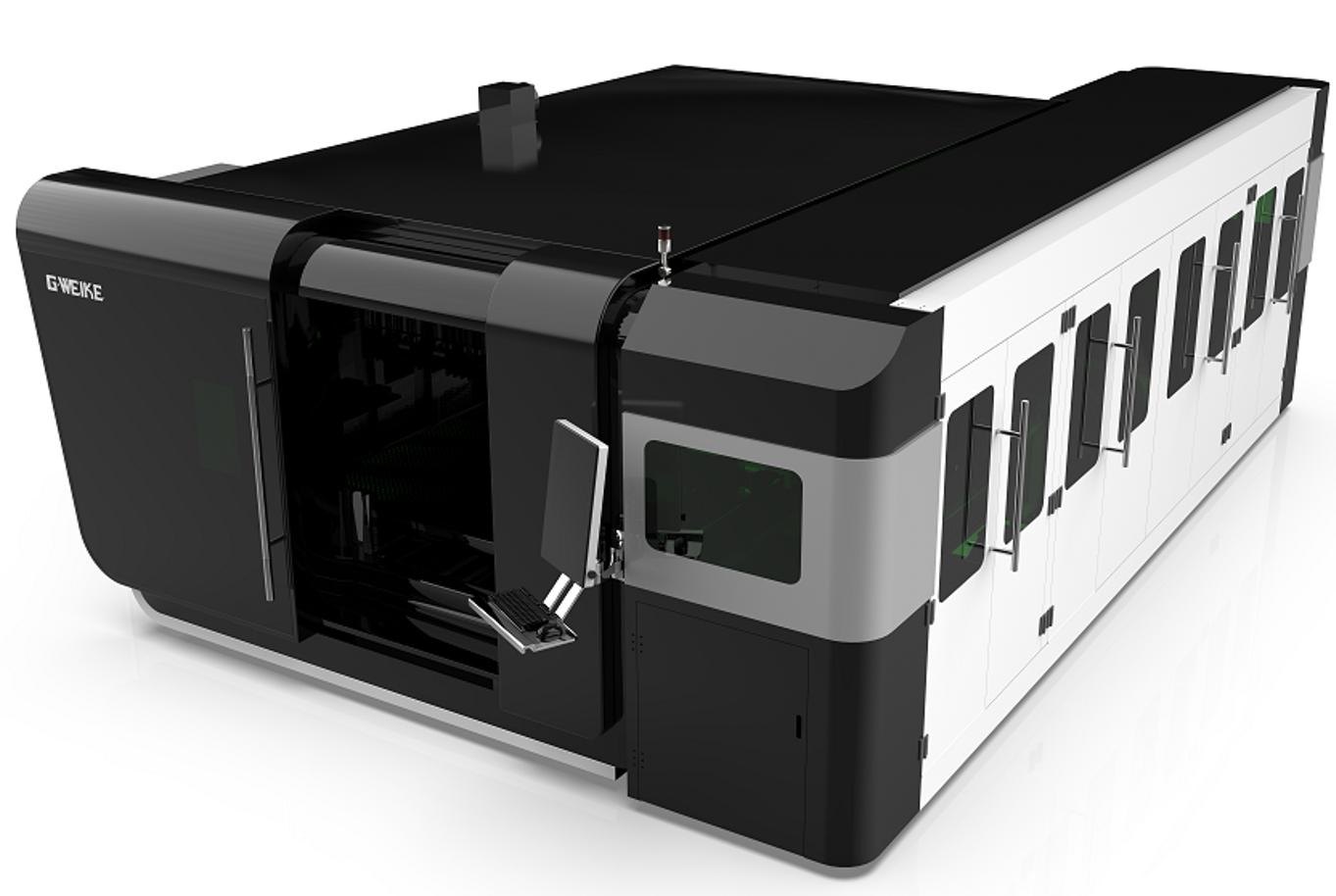

We offer a combined CNC laser, which combines the possibilities of cutting into sheets and pipes, it is a universal cutting laser in the GAR version. This design is based on the high end GA laser machine and is equipped with a fourth rotary axis, on which you can cut pipes and rods. As standard, the rotary axis of this fiber laser is equipped with a chuck with a maximum tube diameter of 220 mm. Supports for 3D materials are also a matter of course. The work surface for both sheet metal burning and pipe burning is completely covered, which meets all safety requirements. Even with this version of the fiber cnc laser, you do not lose the possibility of two exchangeable tables. The professional and high-quality GWEIKE GAR laser cutter expands your possibilities in cutting metal materials.

|

Advantages of CNC laser GAR

|

Sample configuration: CNC laser LF-3015GAR 3kW

Technical parameters

|

Included in the price

|

Optional accessories

|

I am interested in a combined GAR laser machine

The main working surface of the CNC laser and the 4th axis for cutting into pipes and profiles are completely covered for maximum safety. The loading of metal sheets into the laser cutter takes place via an exchangeable table in the back of the laser machine. Loading 3D material is from the side of the cutting laser, where there are two chucks and material supports. The rear chuck is movable and feeds material to the cutting head of the CNC machine. Removal of finished blanks is possible from the front of the machine and sheet metal blanks are removed again from the exchange table. The entire firing process is monitored by a camera system as well as the surroundings of the CNC laser cutting machine. The operator controls the fiber laser via a control panel with an HD monitor and a powerful computer. The machine software is already equipped with an automatic nesting nesting as standard to minimize material waste. The laser cutting machine can be connected to the company network and data can be sent to it online.

Basic equipment of CNC laser GAR

Already in the basic price you get the entire combined laser with a covered work surface and two exchangeable tables plus a fourth rotary axis. Furthermore, all accessories, which are a voltage stabilizer, cooling equipment, air-conditioned box with electronics and a filter unit with a fan for flue gas extraction. Part of the basic equipment is the mentioned camera system for monitoring work with CNC laser. Of course, you also get a laser source from the world-famous manufacturer IPG with the required power and a process head with automatic focal length search. The basic price includes several services that we provide as an official supplier of CNC laser cutters:

- Transport of a CNC laser to the destination to your production

- Composition and placement of the laser machine at the agreed location

- Fiber laser installation, including setting suitable parameters for the required material

- We will train the operator of the laser cutter on its operation and maintenance

- We provide a standard warranty period of at least 2 years

- You have online and telephone support with the ability to connect to the machine remotely

Ordering a laser cutting machine:

We will first find out your need for the cut material and its thickness. Based on this information about the laser cutting machine, we are able to offer a suitable size of the work surface and optimal performance of the CNC laser. We will send you an individual offer for the agreed laser machine, including price and technical parameters. We will arrange a personal demonstration for one of our customers. We have several installation lasers, so you won't have to weigh long distances. After a personal presentation, we will agree on the conditions of the CNC laser sale and send you a draft purchase agreement. After approval and signature, we will provide everything necessary for the delivery of the burning machine. Subsequently, it informs you about the date of delivery of the laser machine to you. It is always and exclusively a new machine with CE certification. Ordering a CNC laser is easier with us than ever before.

Do not hesitate and come and see for yourself. Quality GWEIKE CNC lasers will help you grow your business.