What is the power of the laser source?

Are you thinking about buying a CNC laser and are hesitating how to choose a powerful laser cutting machine? Based on many years of experience with laser machines, we will be happy to recommend the appropriate performance for your materials. The power of the laser source is given in Watt or kW. Today, cutting laser outputs in units of kilowatts are quite common. Fiber laser is now the most widespread technology in industrial metal cutting. It gets its name from the way the laser beam is guided through the fiber. The guided beam is then directed at the burned material by the laser head. But how to choose the power of the fiber laser correctly?

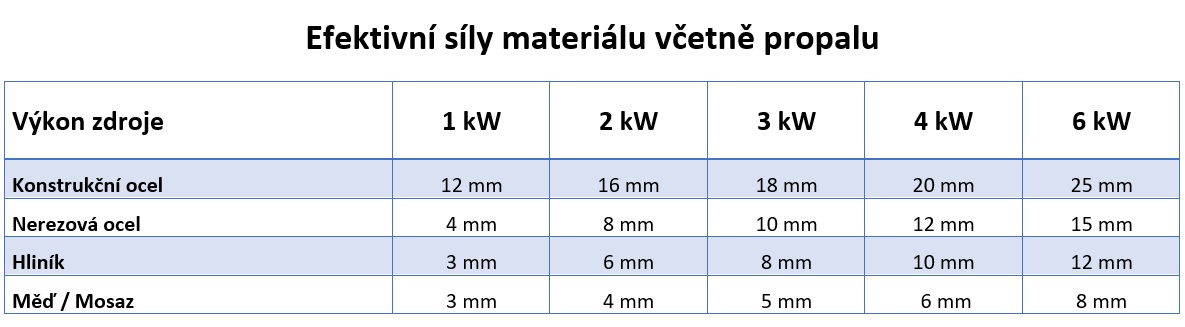

The performance of a CNC laser is mainly determined by two things. First of all, how thick materials can you cut and how fast will you cut them. The first mentioned is absolutely crucial. The correct performance of the fiber laser determines its possibilities in terms of the strength of the cut materials. Laser cutting machines can cut all industrial metals, but they have different characteristics. The least durable of them is classic structural steel, for example S235 or S355. With the same power of the laser source, it achieves the highest possible split power. Next in order is stainless steel, aluminum and the most resistant are copper and brass. Differences with an equally powerful CNC laser are up to tens of mm. Below we have a clear orientation table for you with the maximum sheet thickness according to the performance of the laser machine.

The table shows the most common performances of CNC lasers. It is of course possible to have a higher power laser source (up to 20 kW). The stated maximums are within the effective use of the laser cutting machine. When the process head approaches from the edge of the material, the maximums are higher. At the same time, it is possible to occasionally reach higher maximums, including burnout, than our table indicates. From the opposite end, material minima begin at around 0.1 mm.

So how to choose the right CNC laser power?

Be sure to proceed from your maximum expected thicknesses of all processed materials, including a reserve for the future. The lifespan of a CNC laser cutter is over ten years, and it is better to expect a possible increase in possibilities in the future. The performance of the entire CNC laser cutting machine can be increased over time by replacing the laser source. However, it is also necessary to take into account the replacement of the cooling device, which must always be adequate to the performance of the laser cutter. Cutting speeds do not increase dramatically with higher power. Rather, it is precisely in the maximum material thicknesses that higher performance will be faster. On thin materials, the power of the laser source is systematically reduced. Higher power of the cutting laser, on the other hand, has a positive effect on the piercing speed.

When bevel cutting sheet metal or 3D materials on a tube laser, the specified values may not apply. We recommend always consulting the specific application together with the request or during a personal visit. We will be happy to recommend the appropriate laser performance according to your idea of the planned production. Based on our experience, we will also help you with additional equipment for CNC lasers. We are your partner in laser cutting.